-

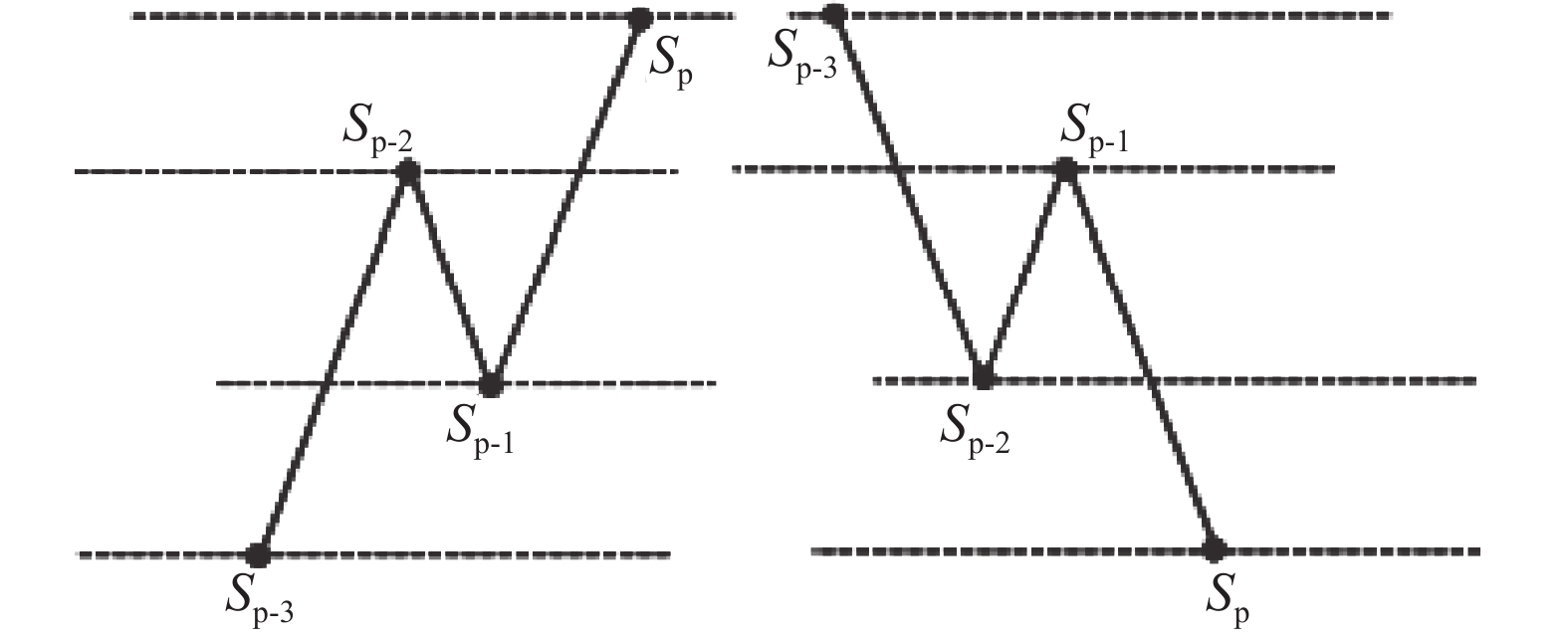

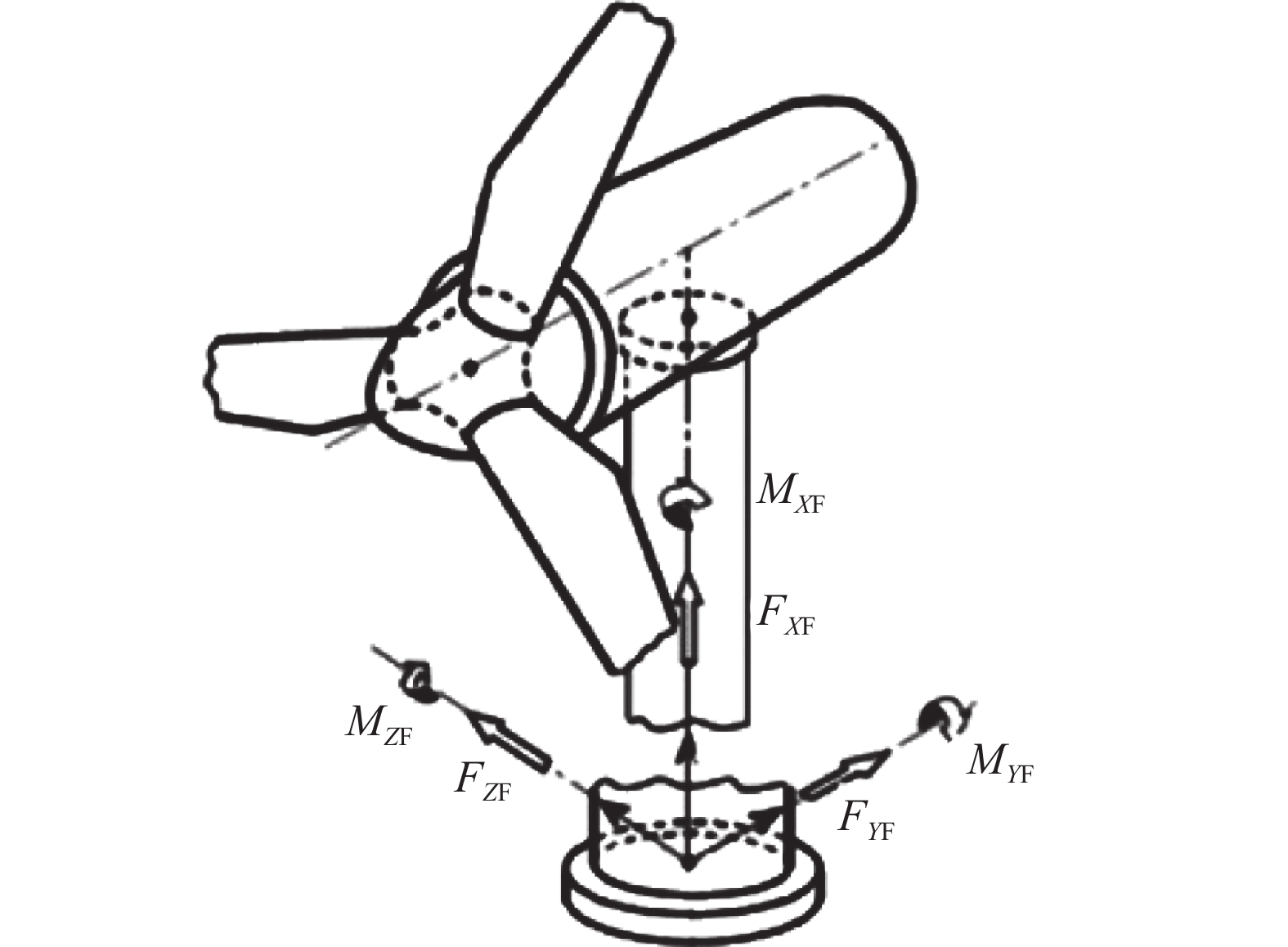

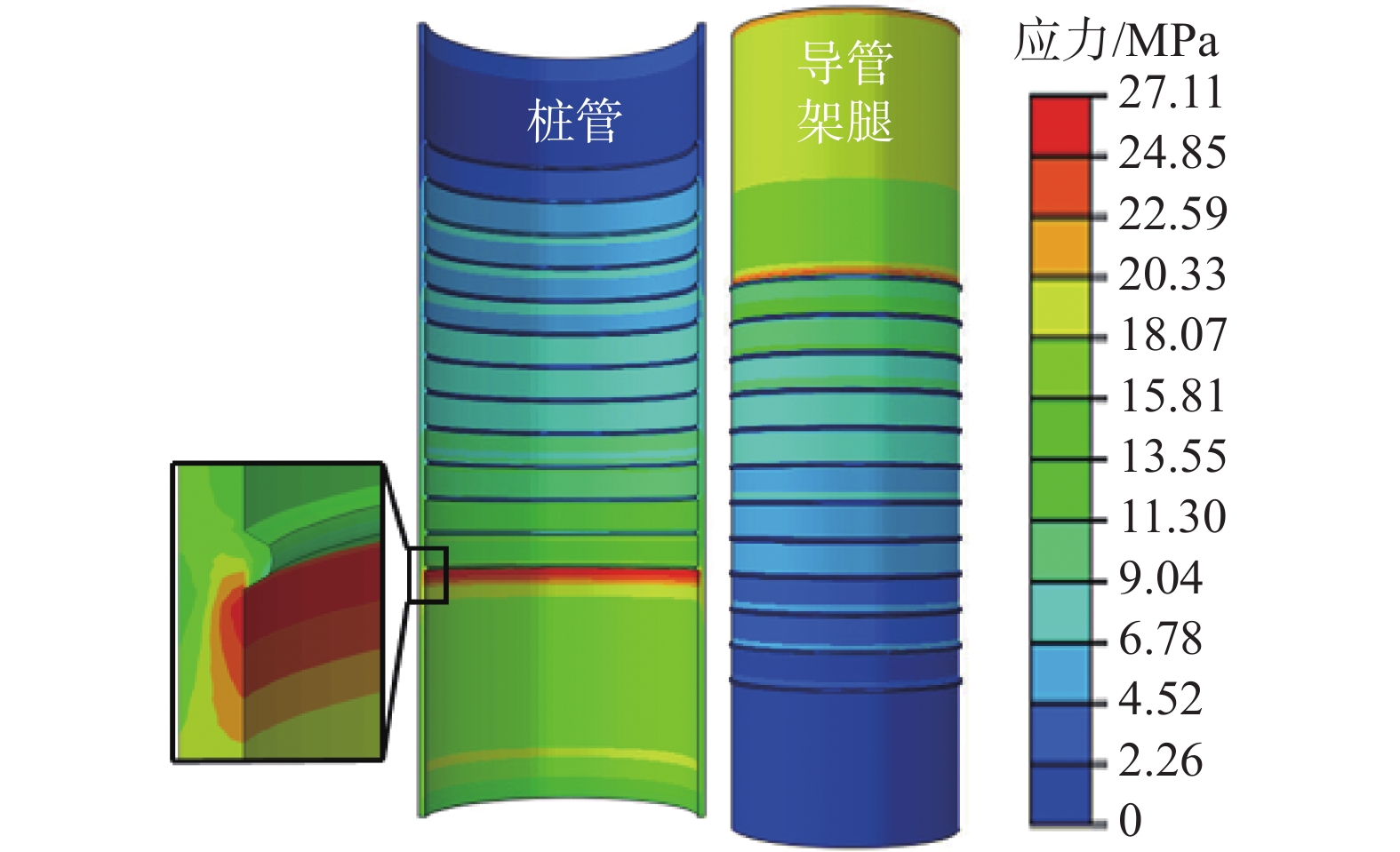

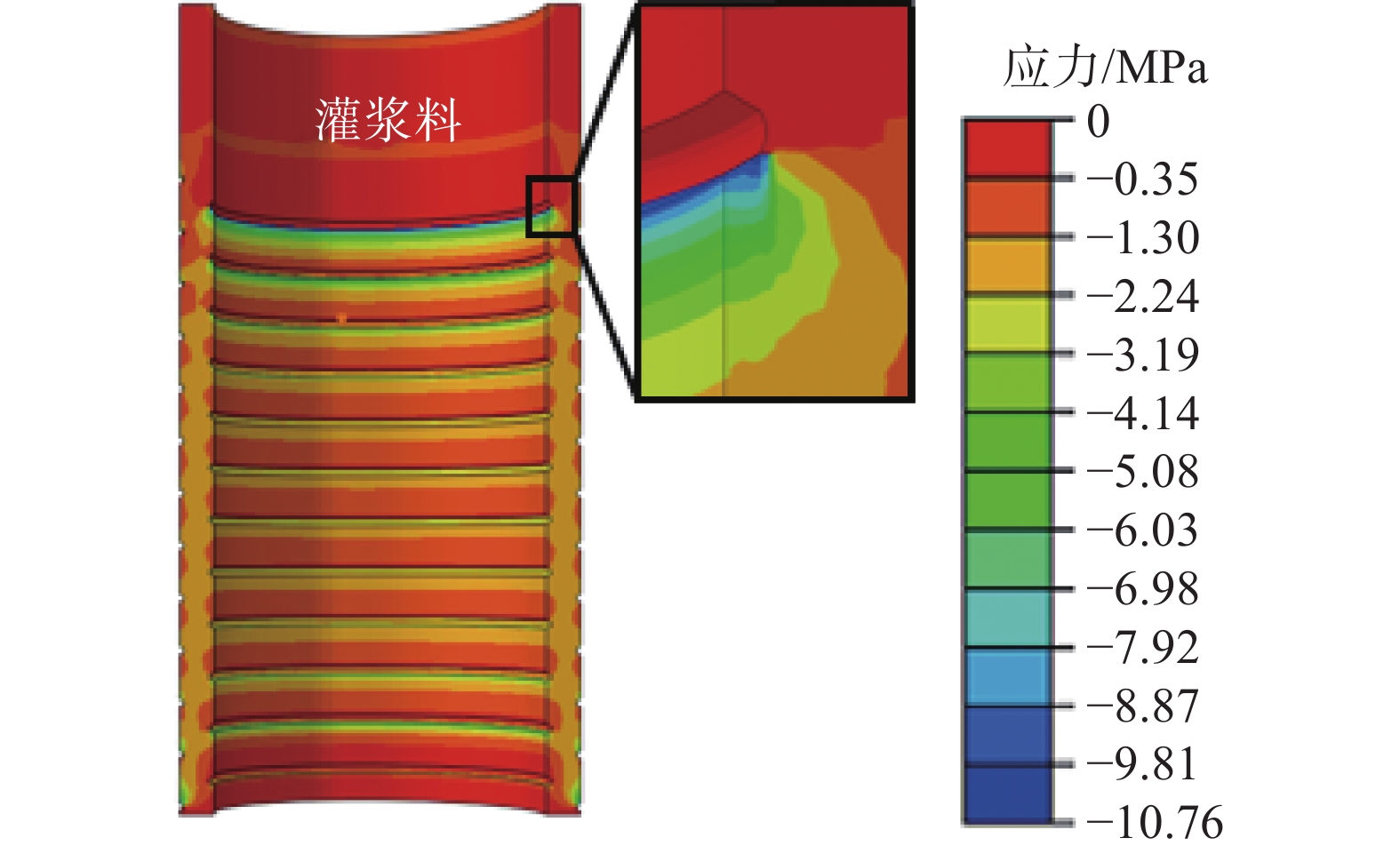

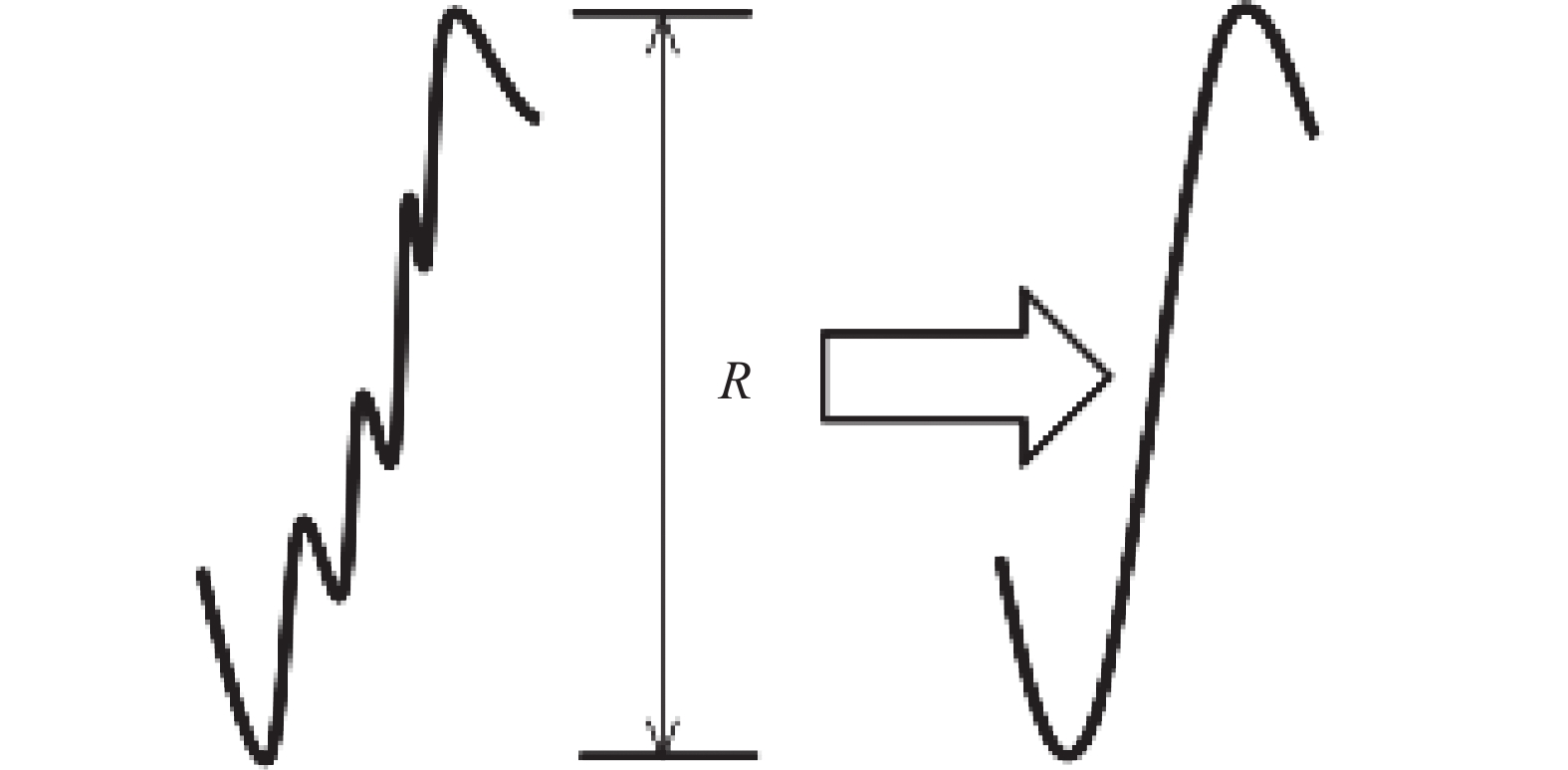

摘要:目的 由于荷载的时变性与随机性,海上风电基础结构中的灌浆连接段疲劳问题突出,为确保海上风电基础服役安全性,需要研究连接段疲劳性能演化规律。方法 从有限元数值模型出发,将马尔科夫荷载矩阵转化为灌浆连接段关键位置处的应力,并结合材料的S-N曲线和线性累积损伤准则,实现对灌浆连接段的疲劳性能评估。结果 通过对灌浆连接段有限元模型分析可知,在轴向荷载作用下,钢结构产生的累积损伤值大于灌浆材料,但均小于DNV规范中的限值。结论 说明在该风机荷载作用下,灌浆连接段内的两种材料均不会发生疲劳破坏,风机基础结构是安全的,同时该分析方法也是有效的。Abstract:Introduction Due to the time variability and randomness of load, the fatigue problem of grouted connections in offshore wind power is serious and it is necessary to research into the fatigue performance of grouted connections to ensure its safety operation.Method Based on the finite element numerical model, the Markov load matrix was transformed into the stress at the key position of the grouted connections in this study, and combined with the S-N curve of materials and the linear cumulative damage rule, the fatigue performance of the grouted connections was evaluated.Result The finite element model of grouted connections shows that the cumulative damage of steel materials under axial load is greater than that of grouting materials, but less than the limit of DNV specification.Conclusion This study shows that fatigue failure will not occur in the two materials in the grouted connections under the specific load, the structure of turbine is safe, and the analysis method is effective.

-

Keywords:

- finite element /

- Markov matrix /

- grouted connections /

- fatigue analysis /

- structure intensity

-

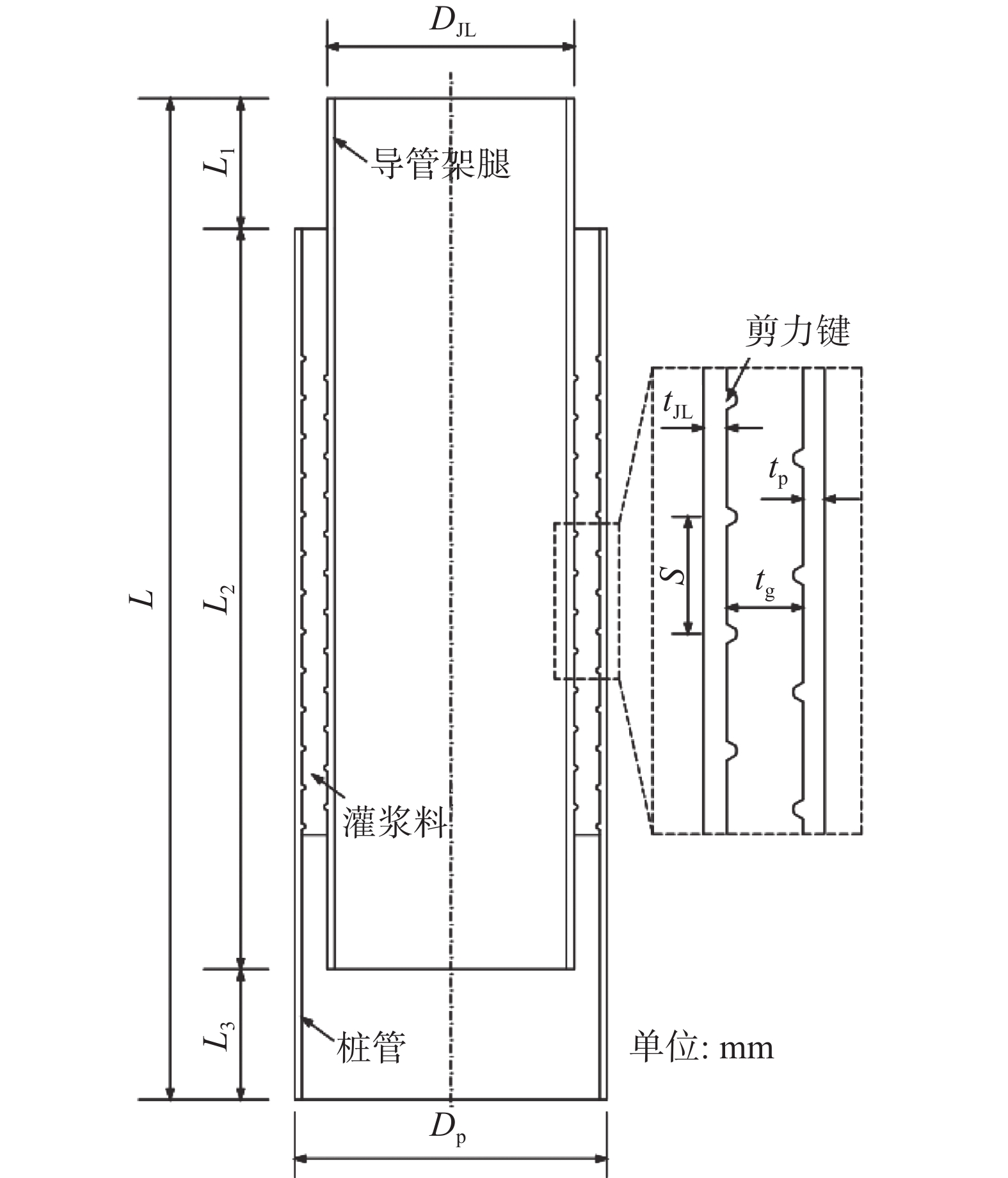

表 1 灌浆连接段数值模型几何尺寸

Table 1 Geometrical dimension of numerical models for grouted connections

mm 内部导管架腿 外部桩管 连接段长度 DJL tJL Dp tp L L1 L2 L3 1 900 60 2 400 55 7 700 1 000 5 700 1 000 表 2 焊趾处钢结构较大的损伤值 Di 及相应的循环荷载

Table 2 Damage value Di of steel structure at toe and corresponding cyclic load

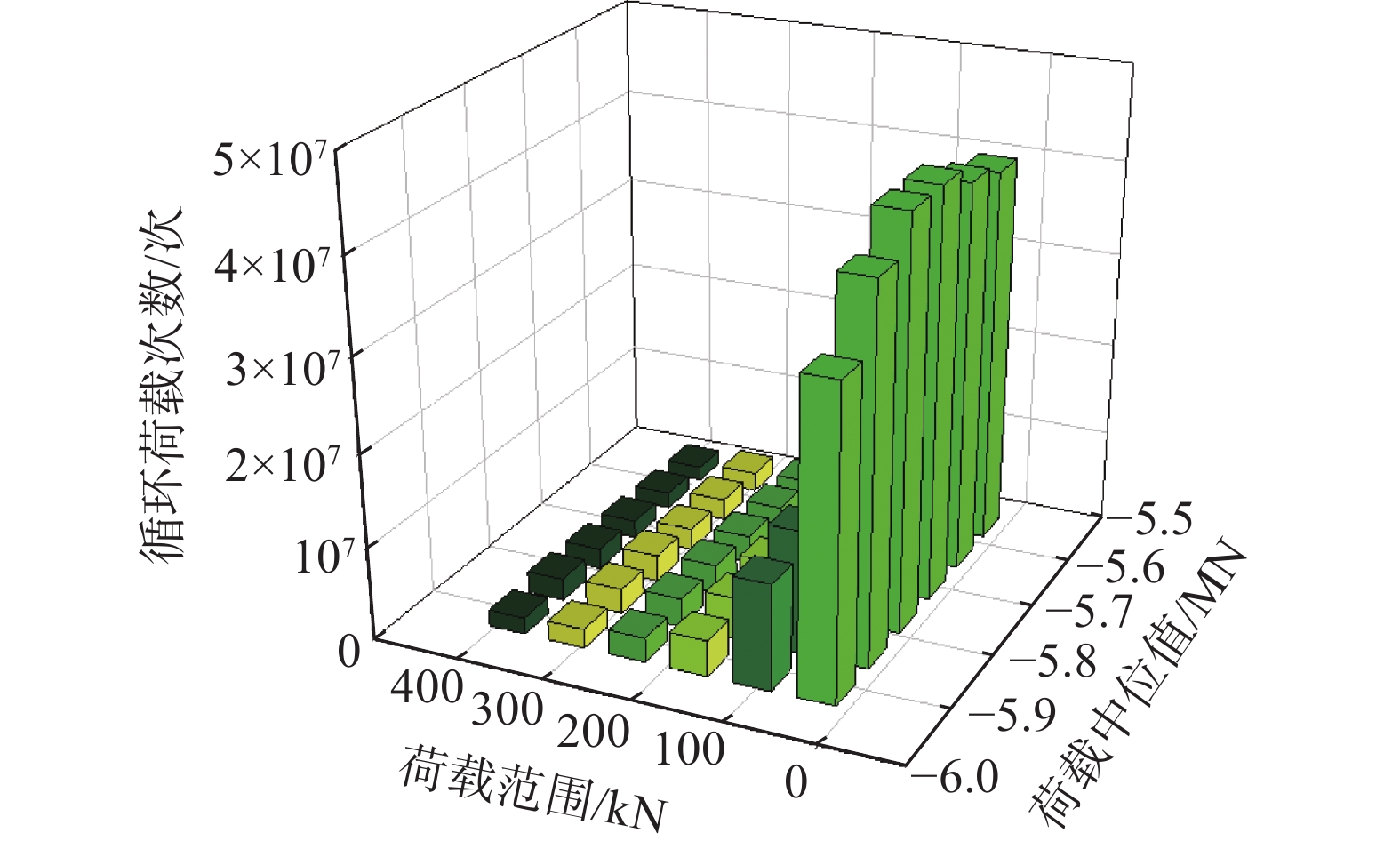

平均值/MN 应力范围/MN ni Ni Di −5.145 1.715 6.329 2×104 1.927×1011 3.285×10−7 −5.215 1.995 2.851 9×104 9.076×1010 3.142×10−7 −5.215 1.855 3.575 4×104 1.305×1011 2.739×10−7 −5.495 1.785 3.661 2×104 1.606×1011 2.280×10−7 −5.145 1.785 3.147 3×104 1.577×1011 1.996×10−7 −4.305 1.365 1.099 84×105 5.743×1011 1.915×10−7 −5.565 1.715 3.710 4×104 1.969×1011 1.884×10−7 −5.565 1.925 1.971 6×104 1.105×1011 1.784×10−7 −5.565 1.855 2.280 9×104 1.330×1011 1.715×10−7 −5.145 1.925 1.797 5×104 1.081×1011 1.663×10−7 表 3 焊趾处灌浆料较大的损伤值 Di 及相应的循环荷载

Table 3 Damage value Di of grouting materials at toe and corresponding cyclic load

平均值/MN 应力范围/kN ni Ni Di −5.775 35 4.388×107 1.156×1019 3.795×10−12 −5.705 35 4.390×107 1.188×1019 3.696×10−12 −5.845 35 4.012×107 1.126×1019 3.563×10−12 −5.635 35 4.170×107 1.220×1019 3.419×10−12 −5.355 35 4.395×107 1.338×1019 3.284×10−12 −5.425 35 4.238×107 1.308×1019 3.241×10−12 −5.565 35 4.034×107 1.248×1019 3.232×10−12 −5.495 35 4.104×107 1.278×1019 3.212×10−12 −5.285 35 4.317×107 1.370×1019 3.151×10−12 −5.145 35 4.402×107 1.435×1019 3.067×10−12 -

[1] 刘东华, 元国凯, 陈涛, 等. 海上风电灌浆连接段疲劳机理研究综述 [J]. 南方能源建设, 2016, 3(增刊1): 68-72. DOI: 10.16516/j.gedi.issn2095-8676.2016.S1.015. LIU D H, YUAN G K, CHEN T, et al. Review on fatigue mechanism of grouted connection in offshore wind farm [J]. Southern Energy Construction, 2016, 3(Supp. 1): 68-72. DOI: 10.16516/j.gedi.issn2095-8676.2016.S1.015.

[2] ČERVENKA, J., ČERVENKA, V., PRYL D. Fatigue assessment of grouted connections from high-strength concrete in offshore wind power plants[C]//Czech Concrete Society. 20th Czech Concrete Day, Hradec Kralove, Nov. 27-28, 2013. Hradec Kralove: Czech Concrete Society, 2013: 1–6.

[3] International Federation for Structural Concrete. Fib model code for concrete structures 2010 [M]. Lausanne: Wiley, 2013. DOI: 10.1002/9783433604090.

[4] WILKE F. Load bearing behaviour of grouted joints subjected to predominant bending [D]. Aachen: Shaker Verlag Gmbh, 2014.

[5] SCHAUMANN P, LOCHTE-HOLTGREVEN S. Schädigungsmodell für hybride verbindungen in offshore-windenergieanlagen [J]. Stahlbau, 2011, 80(4): 226-232. DOI: 10.1002/stab.201101414.

[6] LÖHNING T, MUURHOLM U. Design of grouted connections in offshore wind turbines [C]//IABSE Conference. Assessment, Upgrading and Refurbishment of Infrastructures, Rotterdam, The Netherlands, May 6-8, 2013. Rotterdam: Assessment, Upgrading and Refurbishment of Infrastructures, 2013: 410-411. DOI: 10.2749/222137813806501821.

[7] DE JONGE J B. The analysis of load time histories by means of counting methods[R]. Amsterdam: National Aerospace Laboratory NLR, 1982.

[8] DNV G L. Support structures for wind turbines: DNVGL-ST—0126 [S]. Norway: DNVGL, 2018.

[9] 元国凯, 汤东升, 刘晋超, 等. 海上风电机组基础灌浆技术应用与发展 [J]. 南方能源建设, 2017, 4(1): 10-17. DOI: 10.16516/j.gedi.issn2095-8676.2017.01.002. YUAN G K, TANG D S, LIU J C, et al. Grouting technology application and development in offshore wind farm [J]. Southern Energy Construction, 2017, 4(1): 10-17. DOI: 10.16516/j.gedi.issn2095-8676.2017.01.002.

[10] CHEN T, WANG X, GU X L, et al. Axial compression tests of grouted connections in jacket and monopile offshore wind turbine structures [J]. Engineering Structures, 2019(196): 109330. DOI: 10.1016/j.engstruct.2019.109330.

下载:

下载: