-

核电厂是和平利用原子能的大型能源工业设施,因其发电高效、成本低且无空气污染等原因被很多国家所应用。核安全是政府、社会和核能界高度关注的问题,这就使核电厂的安全性至关重要。这种绝对安全性的要求贯穿于核电厂的规划、设计、建设、调试以及运行的全过程。

全范围模拟机(简称FSS)是以真实机组数据为参照,其仿真精度满足以下条件:

1) 25%~100%负荷之间:

对于主要变量,在任意时刻,模型的计算值与参考值之间的偏差应不超过参考值的±1%。

对于要求无死区并跟随设定点变化的一些值,在任意时刻,设定值与模型计算值之间的偏差应不超过设定值的±0.5%。

2) 0~25 %负荷之间:

在0负荷时(冷停堆及热停堆),主要变量的精度应是参考值的±2%,在0~25%负荷之间具有线性关系。对于在0~25%负荷之间要求无死区并跟随设定点变化的一些值,其精度应为相应负荷下的设定值的±1%。

3) 在模拟机连续运行24 h期间,主要变量的偏差应不超过允差要求。

4) 对于辅助变量,在25%~100%负荷之间,其精度应是参考值的±3%,在0~25%负荷之间,其精度应是参考值的±5%。

可见FSS可以对实际机组的各个系统实现真实的仿真模拟,其对核电厂设计优化以及工程验证等是一个重要的验证手段[1]。包括对仪控设计图纸的验证,对实际机组DCS调节系统的控制验证,对主控室人机接口的设计验证,再到对工艺系统的设计改进和新研发堆型的总体运行研究的设计验证,以及对核电厂运行与调试规程的验证,使得模拟机在多个领域可以进行设计验证[2-4]。

作为应对全厂断电事故(SBO)所做的重要改进项,二次侧非能动余热排出(ASP)系统基于蒸汽发生器(SG) 的二次侧闭式自然循环原理,在缺少外部电源的情况下,可以导出堆芯余热[5]。本文基于国内某三代核电机组FSS,以仿真手段验证ASP系统在SBO事故工况下是否满足设计需求。

-

仿真软件系统是模拟机系统运行的关键和开发的重点。FSS仿真系统软件主要是由仿真平台软件和虚拟DCS系统构成的多层次和相互有机联系的大型实时软件体系。

-

核电仿真平台是模拟机开发、运行和维护的软件基础。其作为模拟机的底层操作系统,应具有一体化建模和在线建模功能,能够提供图形化建模环境、高精度建模工具以及高性能计算算法,包含模拟机运行、维护和测试、数据库管理、配置控制、培训记录编制管理所需的各种软件。

仿真平台软件的结构如图1所示:

仿真平台软件具有以下优点[6]:

1) 具有较强的实时性,支持在线建模与修改,修改模型不需要进行任何编译。

2) 图形化功能强,面向对象,快速、有效、高效的平台,建模、测试无需编程知识。

3) 工具齐全,所有建模工具软件、教控台软件与仿真平台一体化集成。

4) 易于与第三方软件、硬件系统、I/O系统和盘台集成。

5) 易开发、易于扩展,可根据需要随时增加模型对象和建模工具。

6) DCS和逻辑系统可通过翻译、模拟、虚拟等各种方式仿真和集成。

7) 提供所有模拟机所需要的仿真功能。

-

1) Level 0为工艺系统接口层,主要功能为:实时对工艺系统与设备运行参数进行监测,根据DCS系统的控制信号对工艺过程进行控制。

2) Level 1为自动控制与保护层,主要功能为:完成数据采集与预处理、保护控制运算、逻辑处理和通信等。

3) Level 2为操作与信息管理层,主要功能为:支持和诊断各类工艺信息以及对记录操作员的动作,以及通过操作设备对机组进行控制等。

4) Level 3为全厂信息管理层,主要功能为:对整个电厂信息进行综合处理,以及响应核应急。

-

核电厂带功率运行工况下的完全丧失给水事故是指正常给水系统失效,且启动和停堆给水系统与应急给水系统(ASG)未能启动或在运行中失效的运行事故。完全丧失给水事故发生后,二回路的热阱功能完全失效,蒸汽发生器(SG)的导热能力将急剧下降,会导致反应堆冷却剂系统不正常地快速升温、升压,给反应堆带来极大的安全隐患[8]。

ASP系统主要执行该类事故情况下的导热功能。应对的工况为全场断电事故(SBO)+SBO柴油机失效+ASG气动泵失效的事故工况。

这些工况主要包括:

- 丧失全部给水;

- SBO叠加 SBO柴油机失效;

- 其他需要ASG启动的事故叠加ASG失效。

ASP系统启动条件为:3台SG宽量程水位同时低于20%叠加2列ASG系统流量低持续60 s。在设计工况下,系统能够带走一回路热量,确保最终热阱不会失效,防止堆芯熔毁。

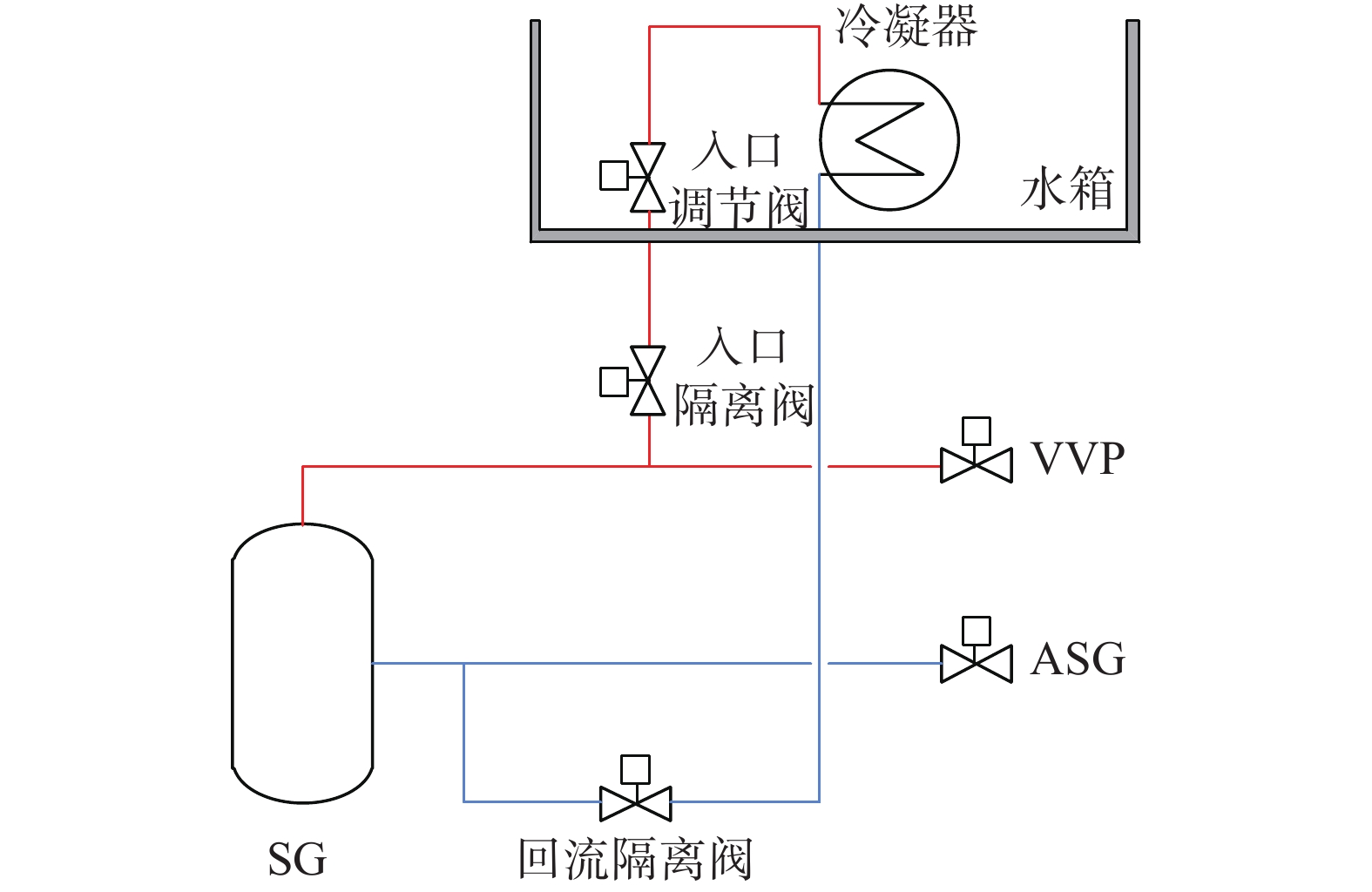

ASP系统分为3 列,每列对应一台SG。每列应能在二次侧8.6 MPa(a)的饱和蒸汽条件下导出至少20 MW的热量。每列包括1个入口调节阀、2个隔离阀和1个冷凝器。每列中的阀门需要依次开启,以缓解启动瞬态的影响。冷凝器浸泡于水箱中,水箱的作用是接收冷凝器传出的热量,并通过水箱存水的蒸发或沸腾等方式将热量排向大气。3列ASP换热器共用一个冷却水箱,水箱位于反应堆厂房的外壁,冷却水箱的水装量可满足事故生发后72 h内对一回路热量有效排出的设计需求。

ASP系统的冷热芯高度差需满足工艺要求,饱和蒸汽入口管线应保持连续上行布置,自然循环回路的最高点位于冷凝器入口前的蒸汽管线上。为利于系统的稳定运行,冷凝回流管线按照先下行布置后上行布置的方式,最低点应低于回流管线进入SG管嘴位置,以使整个回流管线成 U 型结构布置,确保回流管线中形成水柱[9]。

ASP系统如图2所示:

-

模拟机在100%功率下稳定运行, 所有系统运行参数正常, 各有关控制和调节系统, 诸如功率调节、稳压器压力和液位调节等系统均处于自动状态, 安全注入等保护系统则处于相应的在线状态。

-

通过模拟机教控台引入全场断电事故(SBO)+SBO柴油机失效+ASG失效事故工况。事故工况触发后,控制棒失电落入堆芯,将会导致反应堆紧急停堆,汽轮机跳闸。

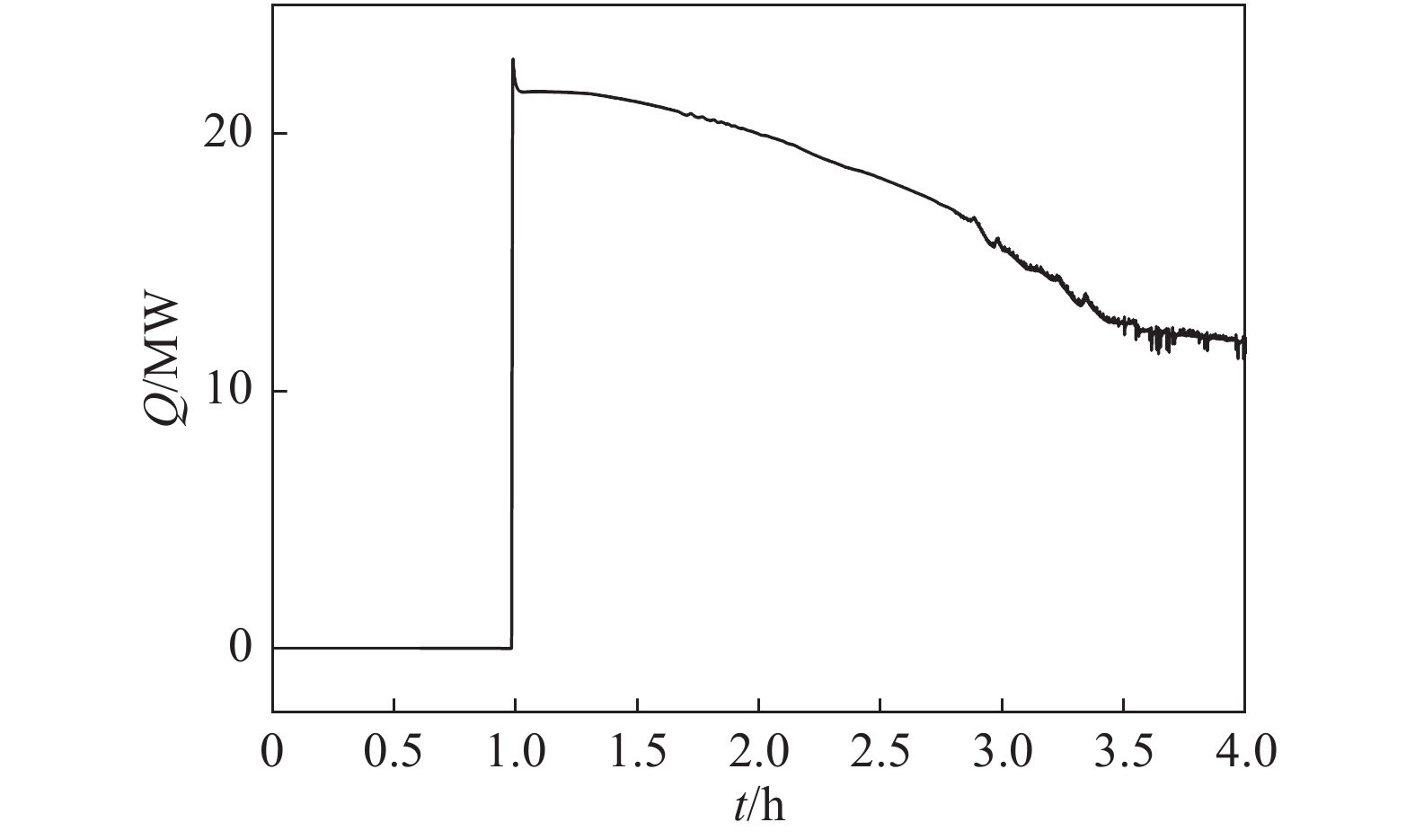

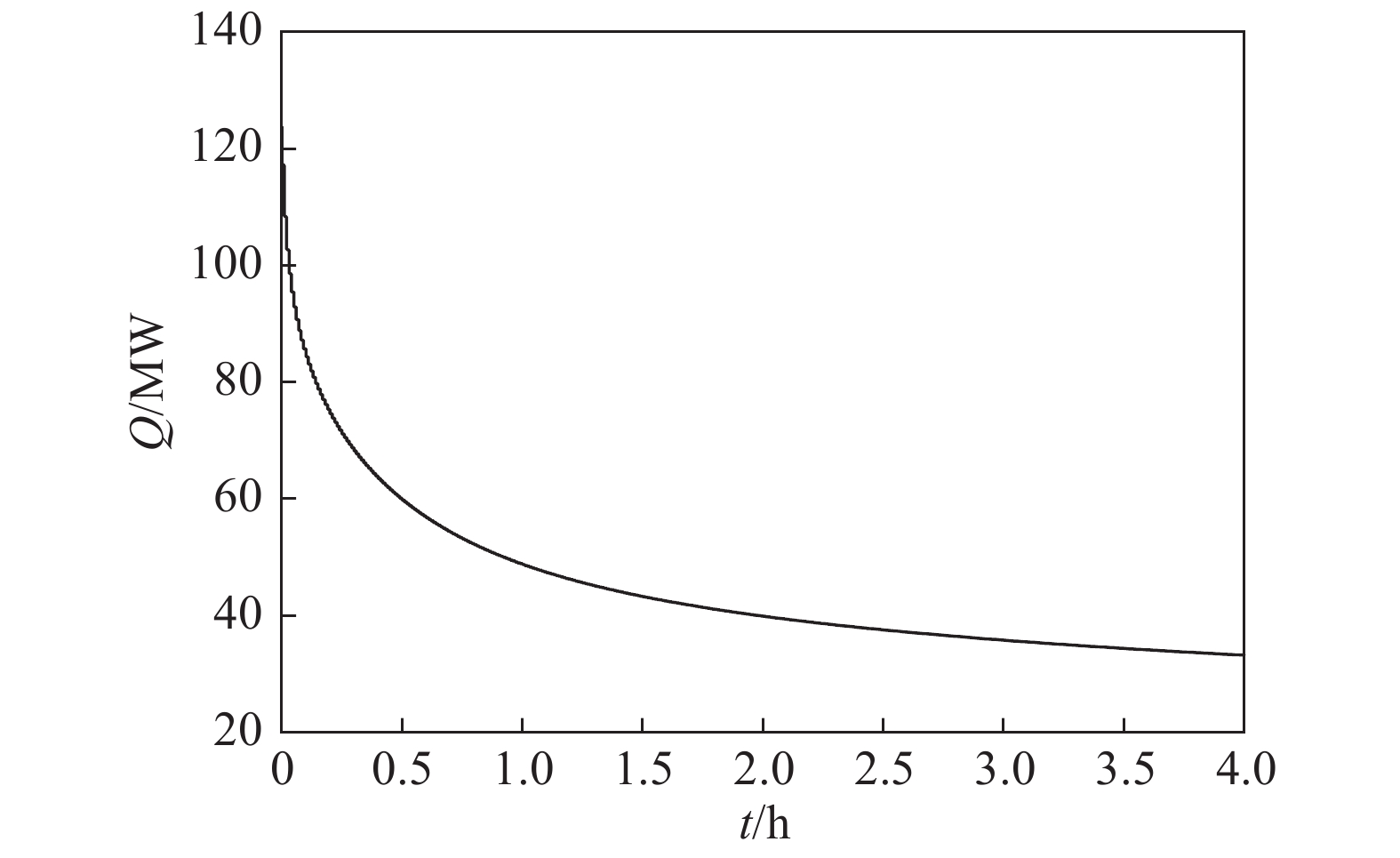

事故工况触发后,ASP系统的主要参数和一、二回路的主要参数随时间变化趋势图如图3~图9。

由以上各图中可以看出,在事故初始阶段,在ASP系统未达到启动条件时,二回路压力升高后,通过大气释放阀( VDA )的调节开启带走一回路的衰变热, SG二次侧压力维持在VDA整定值附近,堆芯出口温度维持在较为平稳的水平。但由于ASG补水丧失,SG内产生的蒸汽通过VDA不断排放至大气,SG内水位不断下降,存在换热管裸露,SG烧干的重大风险。

当事故发生约1 h后,ASP系统触发启动条件自动投运,SG内产生的饱和蒸汽开始进入ASP冷凝器进行冷凝,冷凝水在重力的作用下又回流至SG内,在这个过程中,热量传递至冷却水箱,SG二次侧自然循环建立,冷却剂被SG冷却后,冷热段形成温差,利于一回路自然循环的建立。初始单列冷凝器的换热功率约为20 MW,自然循环流量约为10 kg/s,同时期堆芯核功率约为50 MW,3列冷却环路的运行完全可以导出堆芯余热。随着核功率的下降以及冷水水箱水温的升高,冷凝器的换热功率和自然循环流量逐渐降低。随着饱和蒸汽被逐渐冷凝回流,SG内水位逐渐升高,运行4 h后,SG内水位可恢复至8.6 m,蒸汽发生器传热管始终处于部分淹没状态。随着冷却的不断进行,SG内压力逐渐降低,VDA阀门关闭,运行4 h后SG内压力可降至1.2 MPa。由于堆芯余热被有效排出,堆芯出口温度开始逐渐降低,4 h后,堆芯出口温度降至约为209 ℃,堆芯饱和温度裕度大于20 ℃,堆芯不存在熔毁风险。由于ASP系统的投运,整个SBO事故处于可控状态。

Verification of Advanced Secondary Passive Residual Heat Removal System Based on Full-Scope Simulator

doi: 10.16516/j.gedi.issn2095-8676.2022.02.013

- Received Date: 2022-03-08

- Rev Recd Date: 2022-05-05

- Available Online: 2022-06-24

- Publish Date: 2022-06-25

-

Key words:

- nuclear plants /

- SBO /

- SG /

- full scope simulator /

- FSS /

- advanced secondary passive residual heat removal system /

- ASP /

- simulation verification

Abstract:

| Citation: | LIU Jinchao, WANG Tongsheng, LIN Yaozu, ZHANG Heng, SHA Rui. Verification of Advanced Secondary Passive Residual Heat Removal System Based on Full-Scope Simulator[J]. SOUTHERN ENERGY CONSTRUCTION, 2022, 9(2): 95-100. doi: 10.16516/j.gedi.issn2095-8676.2022.02.013 |

DownLoad:

DownLoad: