-

随着国家海洋战略的提出,海洋风电项目建设如火如荼,在海洋风电场建设的过程中,海底电缆铺设环节至关重要,因此海缆铺设逐渐成为海洋风电研究领域的重要课题[1-3]。为了应对海洋环境的复杂性,海底电缆需要埋设于海床之下,以避免抛锚及拖网等海上作业对海底电缆造成损坏[4-5]。海底电缆需要依赖于埋设机进行铺设,埋设机首先通过机械手将海缆提升至一定高度,随后利用挖沟设备进行海床的开挖,最后进行海缆的放置与埋设。缆线受到机械手向上抬升之后,会形成一个悬跨段,这就导致缆线出现较大的挠曲和变形,引起局部应力的增加,进而可能造成海底电缆的损伤[6-7]。许多学者针对埋设机挖沟埋设过程中造成的悬跨问题开展研究,如刘可安[4]、李修波[8]、和刘志伟[9]等分别通过理论研究、仿真模拟等研究方法,对海底电缆的埋设受力进行研究。研究表明,海底电缆在埋设过程中的屈曲程度受到挖沟深度的影响非常显著[8-11]。

本文以江苏启东市某海上风电场建设项目为工程背景,通过ABAQUS软件,建立海底电缆铺设模型,模拟海缆从缆线抬升至沟槽放置作业的全过程,分析海缆在铺设作业中的应力变化规律。

-

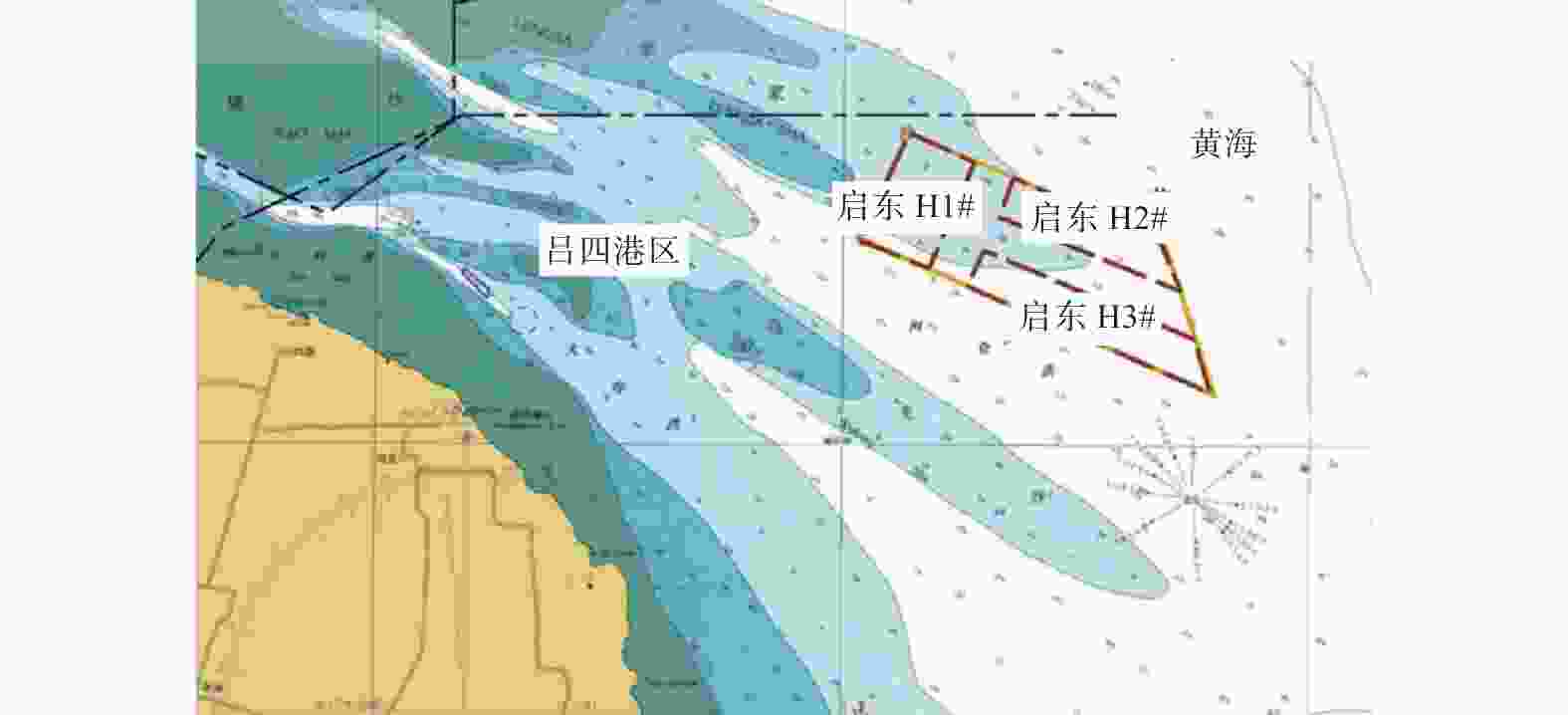

江苏启东市某海上风电场建设场地离岸距离约32 km,海上风电场区位置如图1所示。

海上风电场场区面积约 40 km2,装机容量 250 MW。场区海底地形变化较为平缓,水深在6~13 m之间。场区内海底地形变化较为平缓,属南黄海滨海相沉积地貌单元,地基土表层以粉砂为主。

海底电缆的铺设采用HLA-4型海缆埋设机(如图2所示)。海缆在铺设的过程中要受到多种外力的作用,而影响海缆铺设受力的重要因素就是缆线的铺设速度。根据相关研究以及工程实践成果,海缆若要避免张拉性破坏,埋设速度应尽可能控制在12 m/min以下,且匀速前进。当海洋作业船牵引埋设机行进时,被动牵引力主要由埋设机雪橇以及犁体与海床土质的摩擦力、高压射水水流正面阻力组成。经过多个工程案例试验表明,在一般软土地质以及砂层条件下,牵引力约120 kN。随着埋设机被牵引前进,埋设机上的犁体装置插入土体,进行海床土体的开挖。开挖深度可以通过变幅犁体调整,一般的变幅犁体可开挖的深度为0~4.2 m。埋设机的前进速度受牵引船的控制,通常可在0~20 m/min的范围内调节。

-

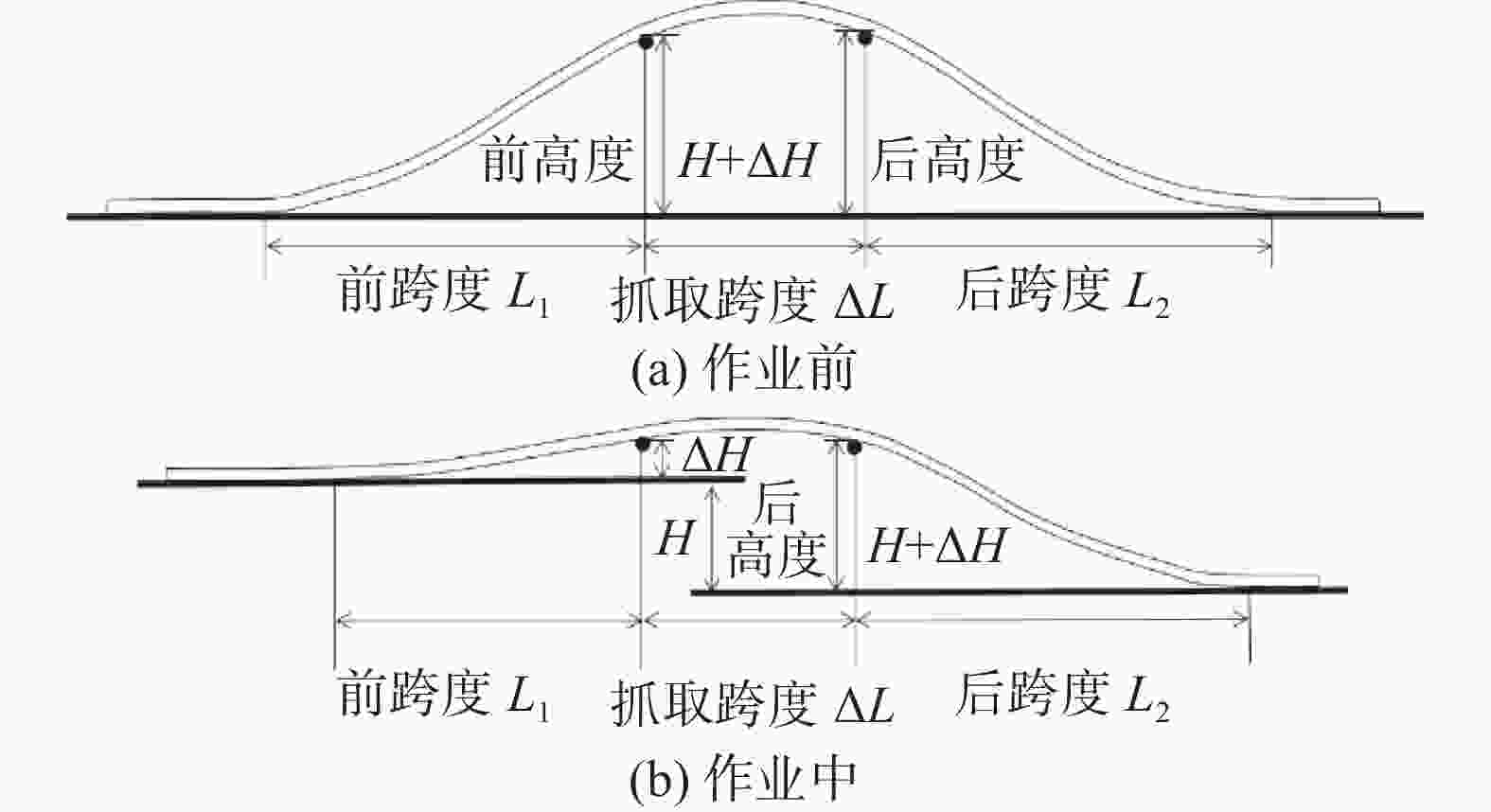

海底电缆在铺设的过程中,需要通过机械手将预先放置于海底的缆线进行抬升,这会导致缆线形成一个悬跨段,如图3(a)所示。缆线的悬跨段一直存在于铺设的过程中,包括缆线的挖沟放置阶段,如图3(b)所示。

Figure 3. Schematic diagram of submarine cable suspension before and during operation[6]

在本文的研究中,海底电缆是均匀连续的材料,并且忽略上覆土对海底电缆的压力作用[12-13]。海底电缆密度ρ=2 230 kg/m3,泊松比υ=0.3,由于海缆内部结构复杂,本文参考内部较为重要的铜芯导体材料的弹性模量值选取等效弹性模量[14-15],E=120 GPa,海底电缆采用弹塑性模型;海底电缆截面是直径D为252 mm的圆形,如图4所示。海床土体密度ρ=1800 kg/m3,泊松比为υ=0.45,弹性模量E=120 GPa,海底土体采用弹性模型。建立海底电缆在挖沟机作业时的数值模型,如图4所示。

模型中海底电缆右端固定,假定右端为埋设段,左端为自由端,无约束;土体完全固定。整个模型采用三维八节点减缩积分六面体单元(C3D8R)网格进行划分,海底电缆网格尺寸为0.05 m×0.05 m,土体网格尺寸为0.125 m×0.125 m(见图4);对电缆网格尺寸0.4 m、0.5 m和0.6 m进行网格收敛性验证,网格尺寸对数值模拟结果几乎没有影响。网格属性设定为结构,以保证网格质量和运算精度,整个模型共划分网格数为72 400。在运行海底电缆铺设的数值模型时,首先需要对模型进行地应力平衡;其次对缆线前后抬升点赋予相应的位移,并通过位移时长来控制缆线抬升的速度;最后,通过海床土体部分的下移来模拟土体开挖,并将缆线自然下垂,模拟土体开挖以及缆线放置。通过模拟缆线抬升与放置的全过程,分析海缆铺设作业的受力状态,开展海缆作业中的力学研究。

-

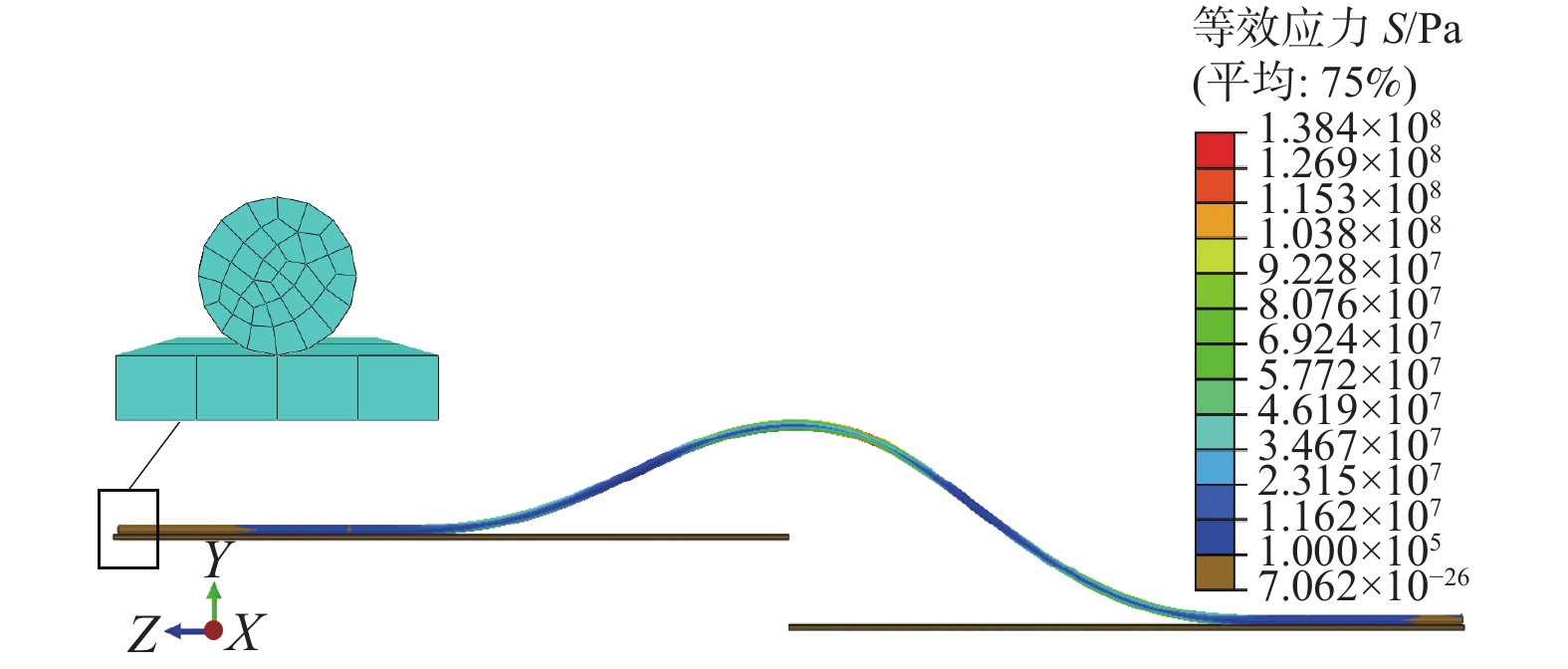

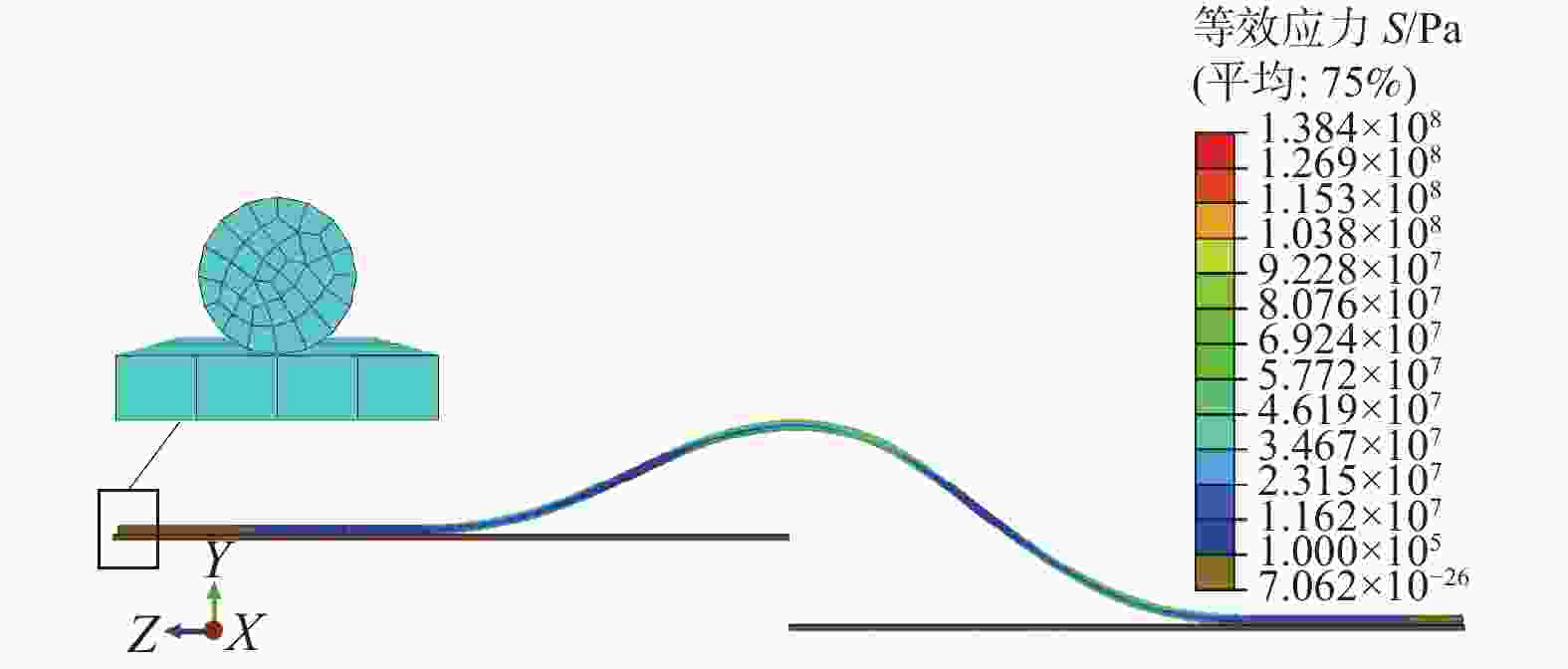

在进行海缆的埋设施工时,机械臂需要通过两个抬升点将缆线提前抬升至一定的高度,导致海缆前后抬升点之间呈现向上的凸曲状,如图5所示。机械臂将海底电缆抬升后,海缆的凸曲变形会导致缆线材料受力增大,所以需要分析海底电缆所能承受机械臂的最大抬升高度,以及海缆在受到抬升后的应力特征,以保证海底电缆在铺设过程中的安全。

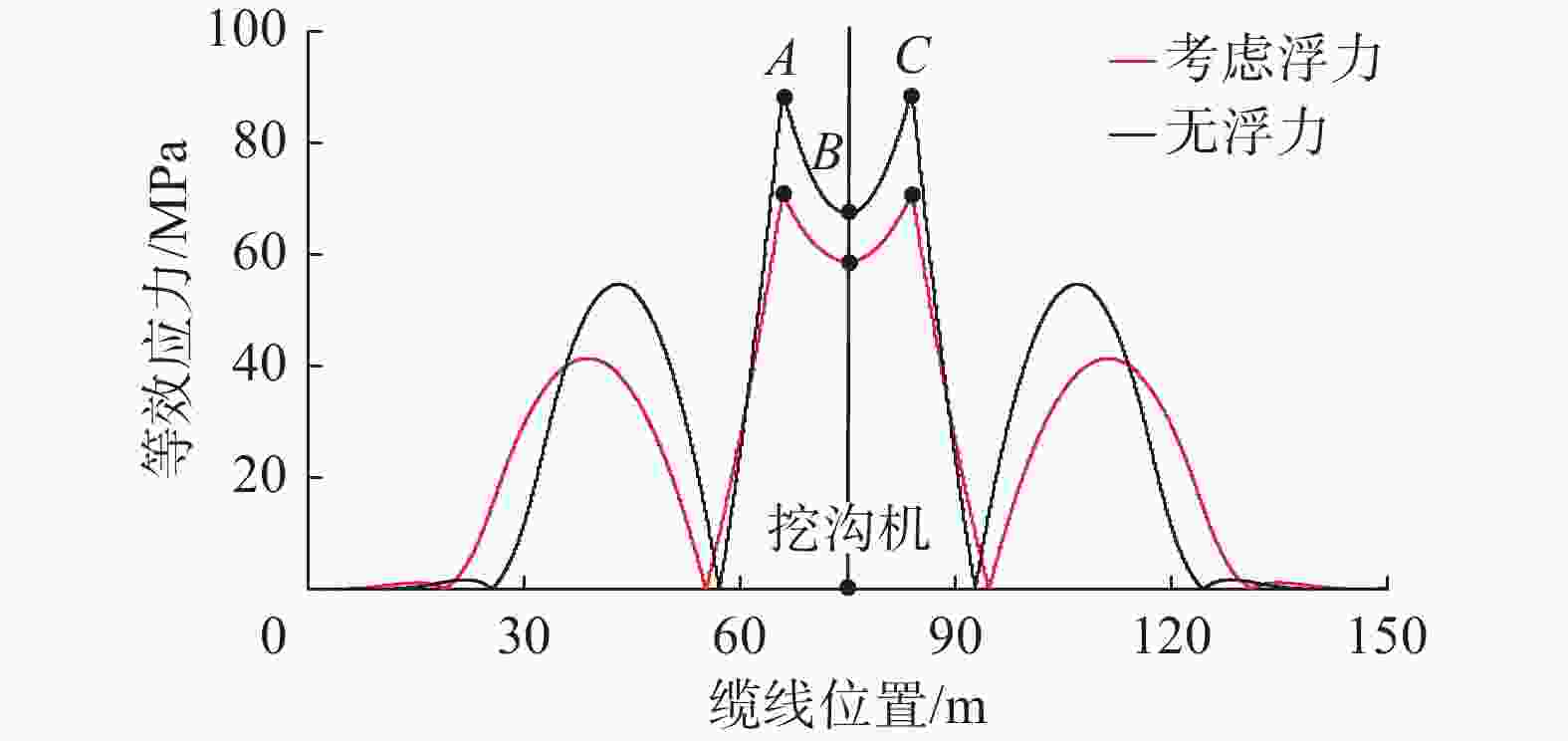

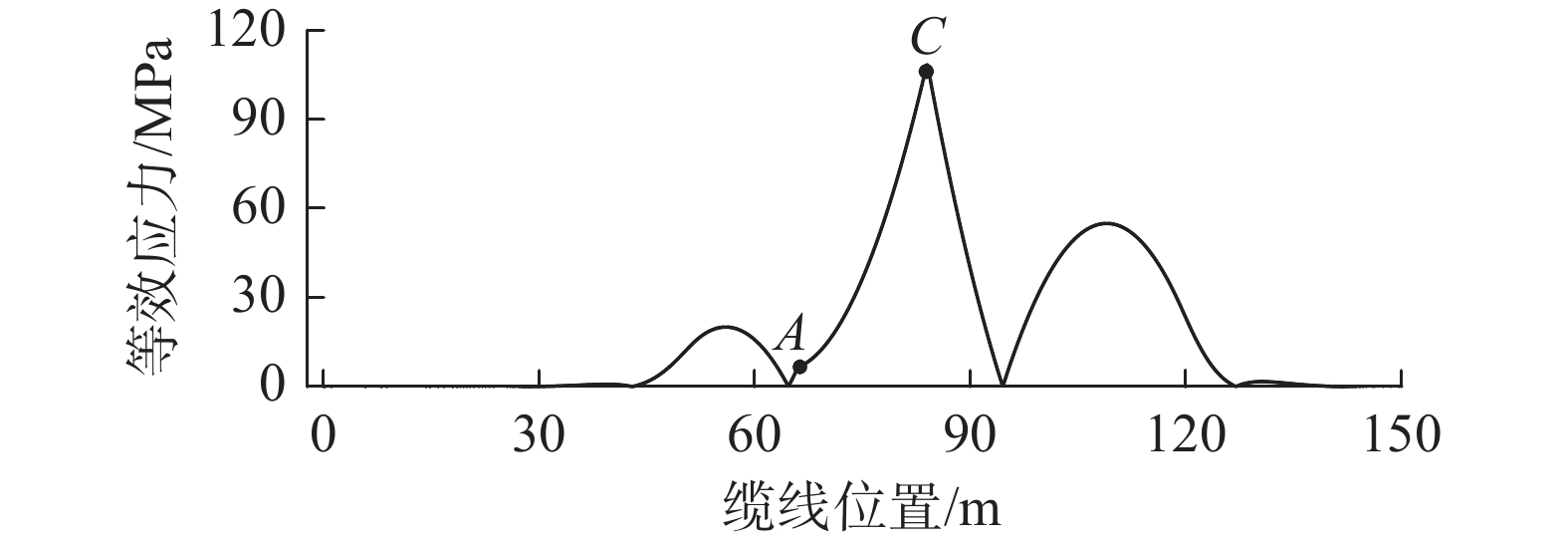

图6表示海底电缆受到机械手抬升后,缆线全跨度的应力分布图。电缆整体长度为150 m,抓取跨度为18 m,提升高度2.2 m,挖沟机位于电缆的中间位置(75 m处)。图6中对比了考虑水的浮力作用与无浮力作用下电缆的应力分布曲线图,图中显示两者应力分布特征一致。从图中可以看出,缆线的提升跨度段(A~C点)应力最大,其中前后提升点(A和C点)受到局部最大的集中应力,提升跨度段中点位置(B点)应力较小。此外,提升跨度两端也出现了应力较大的悬跨段。

对缆线提升后的应力分布来看,缆线局部较大的应力主要集中在海底电缆抬升点(A和C点),该位置受到较大的集中应力,可能造成缆线材料的损伤。因此,在海底电缆铺设作业中,应对提升点位置处的缆线实施相应的保护措施。

-

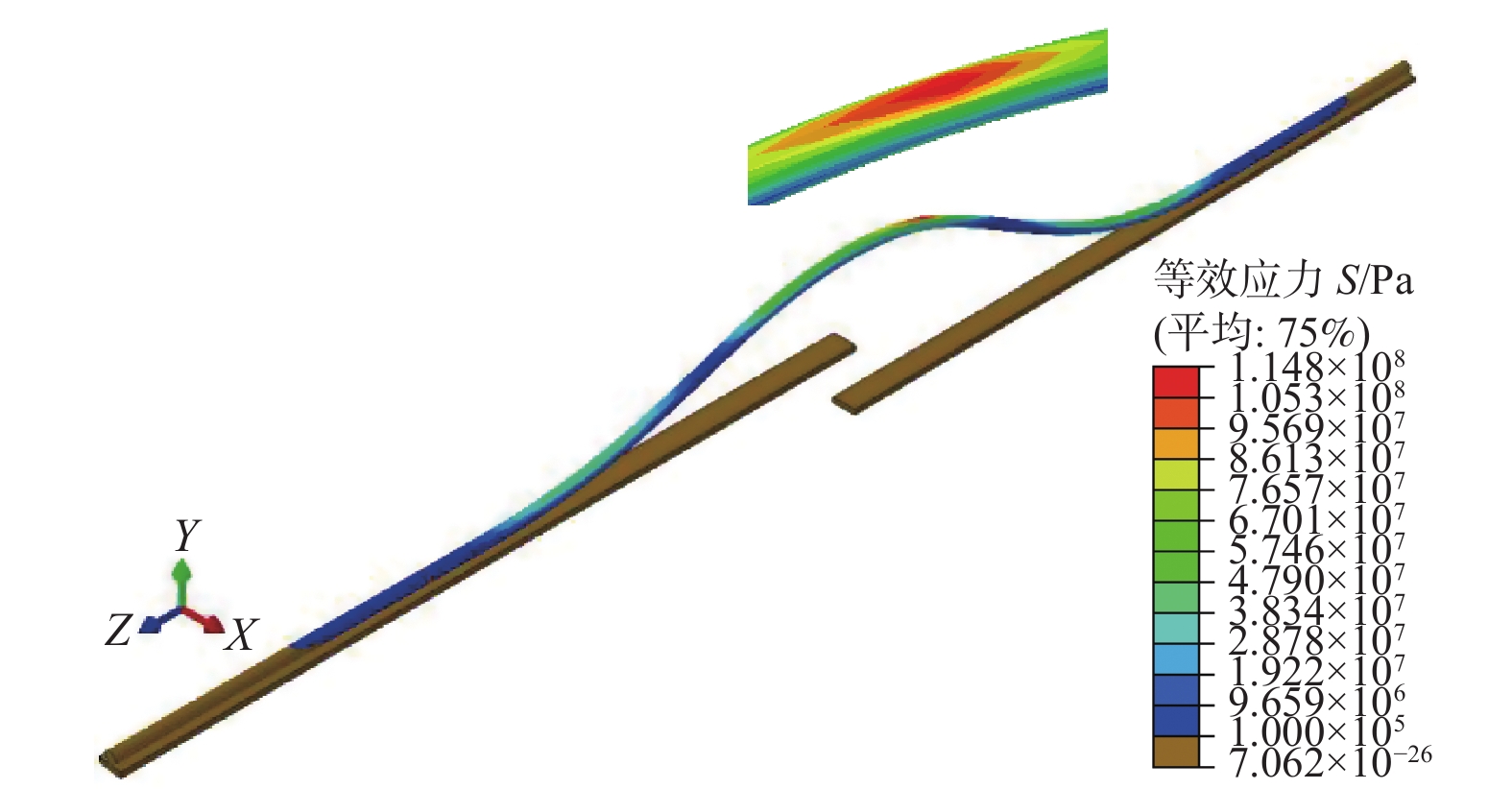

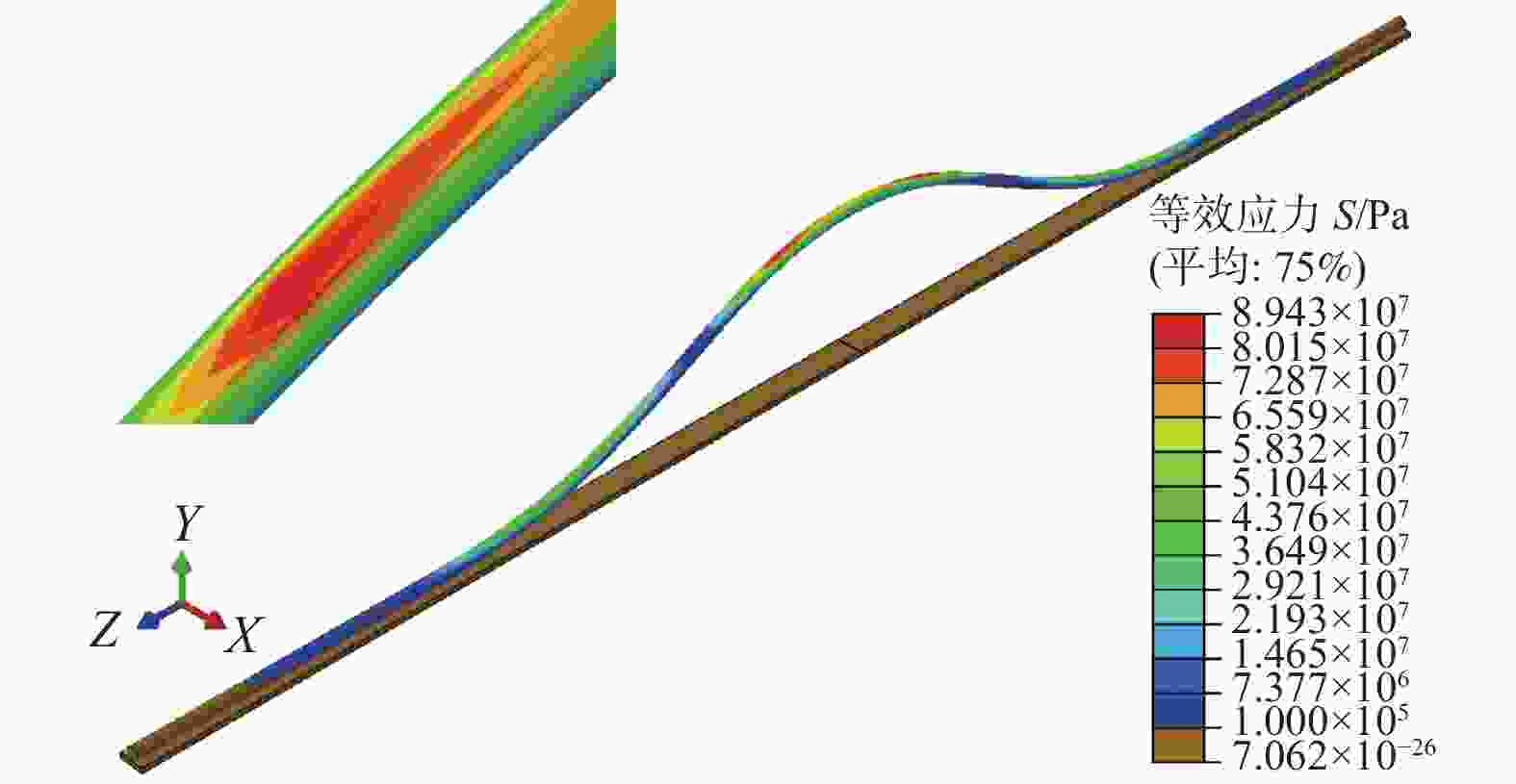

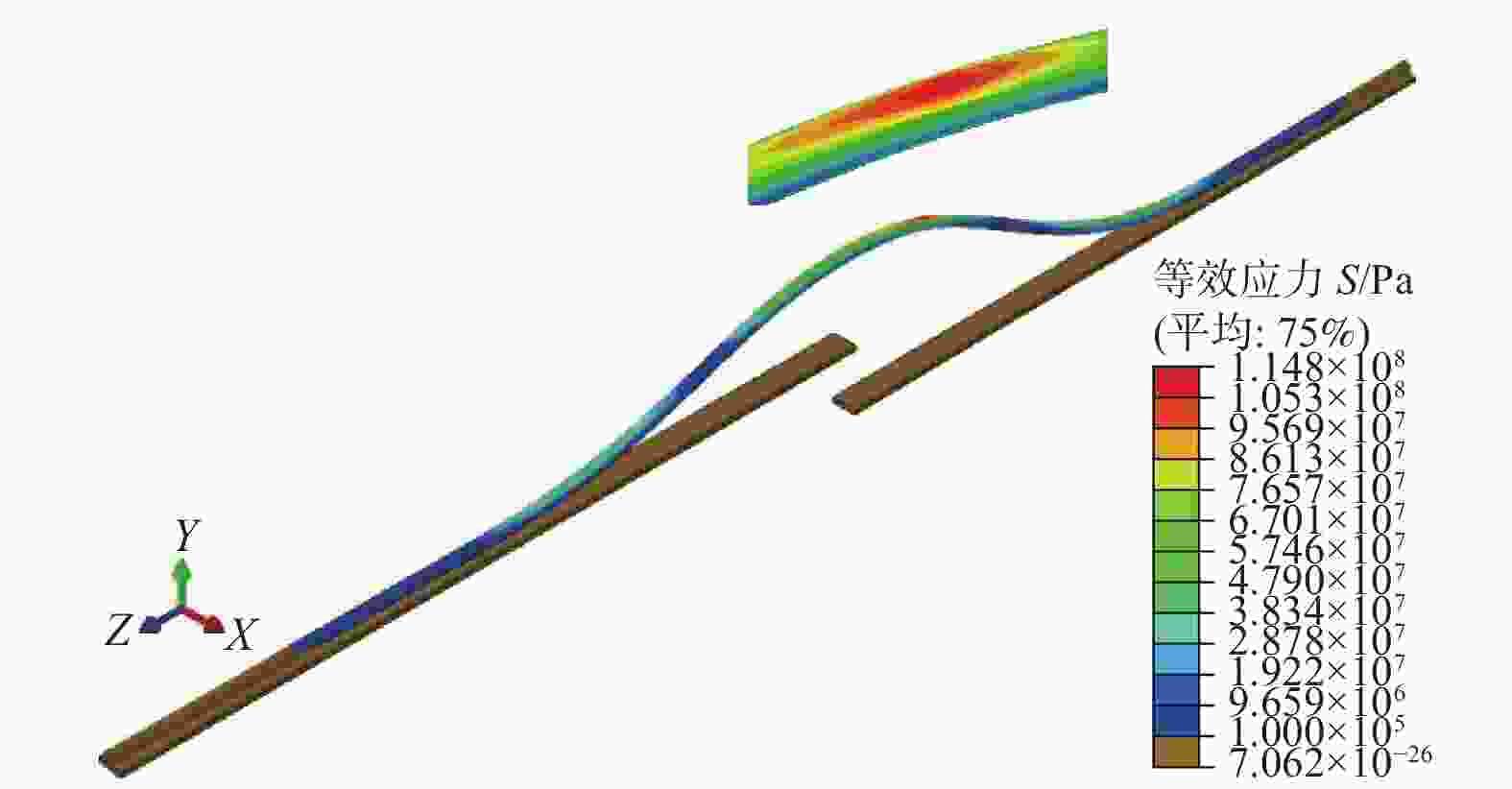

海底电缆在抬升之后,需要使用挖沟机开挖下方的海床土体,以便对缆线进行埋设。在埋设的过程中,海底电缆的后抬升点出现了应力集中。海缆的应力分布情况如图7所示。在图7的数值模型中,海缆埋设的挖沟深度为1 m,海缆前后提升点距离为18 m,机械臂对海缆的抬升高度为2.2 m。

海底电缆埋设过程缆线的应力分布如图8所示。相比于缆线抬升阶段的应力分布情况(图6),海底电缆埋设过程中的缆线主要由后抬升点(图8点C)支撑。相应地C点在埋设作业中相比于埋设作业前的应力显著增大,埋设作业前C点应力为89 MPa,埋设作业中C点应力增大到114 MPa。这种埋设作业造成的后缘提升点应力增大的情况可能使缆线发生塑性破坏。

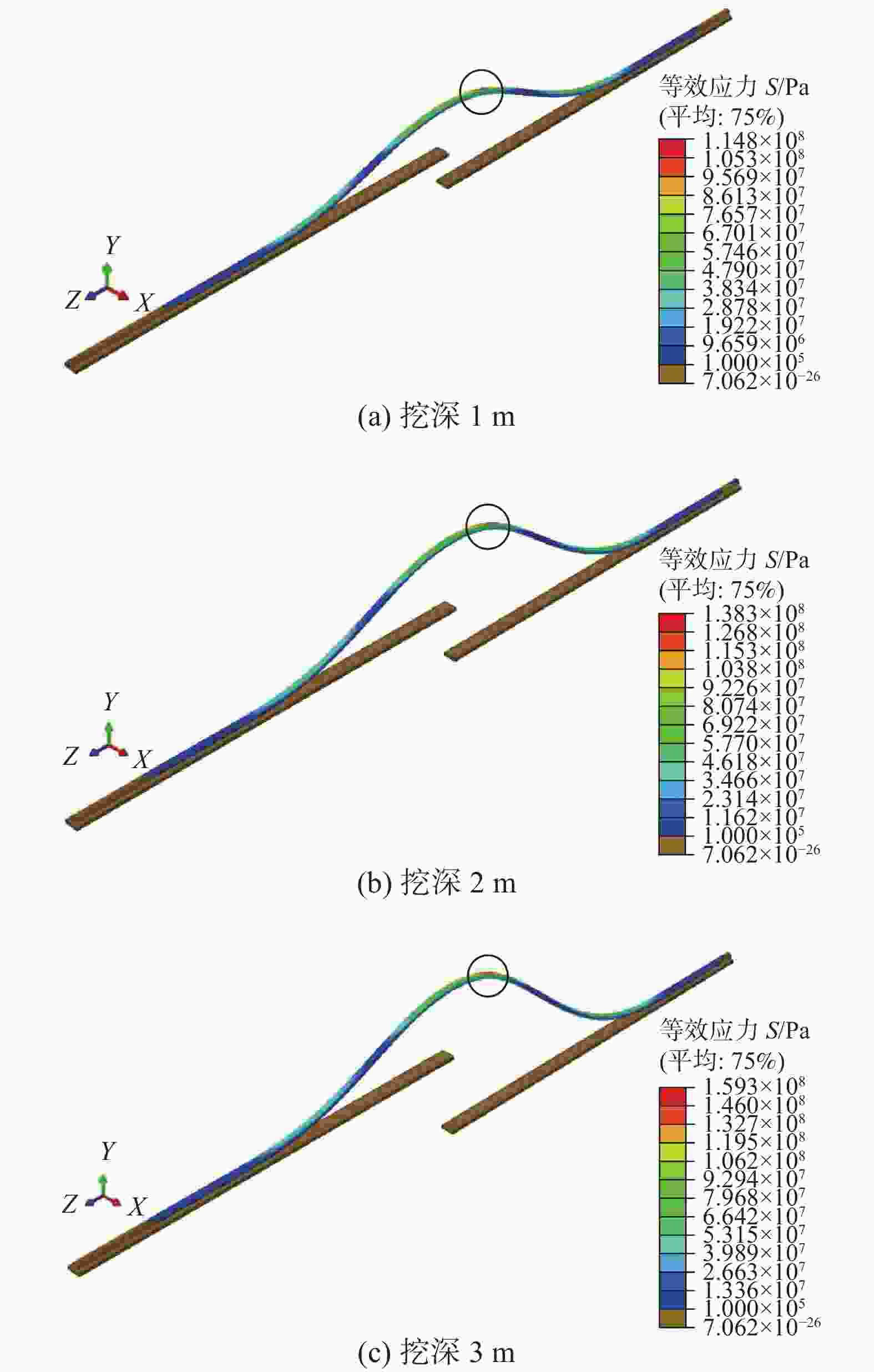

在不同挖沟深度H的工况下,海底电缆数值模拟的分析情况如图9所示。图9中分别选取挖沟深度为1 m,2 m,3 m的工况进行数值分析。

从图9中可以看出,随着挖沟深度H的增加,海缆悬跨段局部最大应力(图9黑色圆圈标识,图8点C)变化非常明显。挖深1 m时局部最大应力为114 MPa,挖深2 m时,局部最大应力增大到138.3 MPa,挖深3 m时局部最大应力为159.3 MPa。相比于挖深1 m的工况,挖深3 m的局部最大应力增大了约39.7%,相比于作业前海床未开挖时海底电缆的局部最大应力89 MPa,海缆埋设作业中C点的应力增大了79%,受力显著增大。

因此,海底电缆在铺设的过程中首先应在合理的范围内尽量降低埋设深度,其次海底电缆的屈服强度参数的设计应着重参考缆线埋设作业中的受力分析结果,尽量避免作业中缆线受力过大而导致的材料损伤。

-

本文采用ABQUS数值模拟方法,以江苏启东某海上风电场项目为工程背景,开展了海缆在埋设过程中的受力分析,得到以下研究结论:

1)海底电缆受到抬升形成悬跨段,抬升点处出现应力集中的情况,海缆埋设作业过程中,后缘抬升点的应力显著增大。因此,在铺设作业中应在海底电缆的抬升点处,尤其是海底电缆埋设阶段,加强对抬升点位置材料的保护。

2)挖沟深度H主要影响海底电缆的后缘提升点应力,对于本文工况当挖沟深度从1 m增大到3 m时,缆线后缘提升点处的应力增大了39.7%。因此,海底电缆埋设深度应在合理的范围内尽量减小,以避免埋设深度过大引起的缆线损伤。

3)埋设前抬升阶段中缆线受到的局部最大应力小于埋设阶段,本文工况中埋设前缆线局部最大应力为89 MPa,而埋设过程中该处应力增大了79%。因此,海底电缆的屈服应力参数选取应着重参考埋设作业中缆线的受力分析结果。

Numerical Simulation Study on Mechanical Characteristics of Submarine Cable During Laying Process

doi: 10.16516/j.gedi.issn2095-8676.2023.01.015

- Received Date: 2021-09-01

- Rev Recd Date: 2021-12-11

- Available Online: 2022-12-15

- Publish Date: 2023-01-11

-

Key words:

- submarine cable /

- stress analysis /

- trenching depth /

- ABQUS /

- numerical simulation

Abstract:

| Citation: | XU Haibo, SHA Xinyu, ZHANG Zhenyu, KU Meng. Numerical Simulation Study on Mechanical Characteristics of Submarine Cable During Laying Process[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(1): 118-123. doi: 10.16516/j.gedi.issn2095-8676.2023.01.015 |

DownLoad:

DownLoad: